Get quick appointment for technical support!

Choosing Between Fused and Non-Fused Disconnects

Oct 23, 2025

In every industrial or commercial electrical system, disconnect switches play an essential role in isolating power safely during maintenance or emergencies. They protect people, equipment, and property by ensuring power can be cut off instantly when needed.

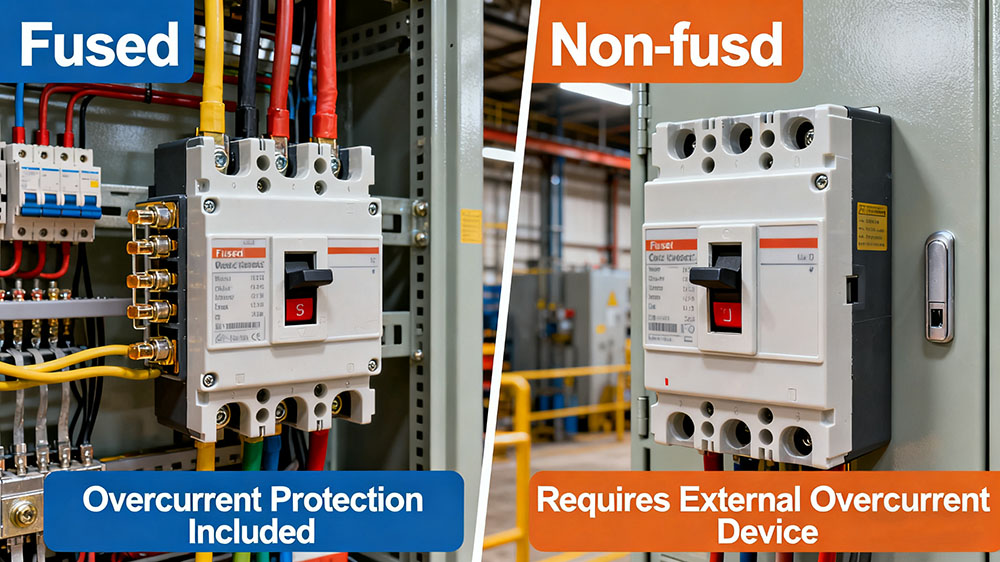

There are two main types of disconnects: fused and non-fused. While both perform the same basic task of disconnecting power, they differ in how they handle overcurrent protection.

Understanding these differences helps you choose the right type for your system, whether you’re managing a factory floor, commercial building, or industrial installation.

What Is a Fused Disconnect?

A fused disconnect combines a manual power switch with built-in fuses. It not only lets you shut off power but also protects from electrical faults such as overloads or short circuits.

When too much current flows through a circuit, the fuse inside the disconnect blows and immediately stops the flow of electricity. This prevents damage to equipment and reduces the risk of fire. Once the fuse is replaced, the system can be safely restarted.

Fused disconnects are commonly used in high-power applications such as motors, compressors, and large HVAC units. They are ideal for situations where the system requires both power control and built-in protection.

What Is a Non-Fused Disconnect?

A non-fused disconnect has a simpler function: it serves purely as an on/off switch. It does not contain any fuses or provide overcurrent protection on its own.

Instead, a non-fused disconnect works together with a separate protective device, like a circuit breaker or fuse panel. It provides a safe way for technicians to isolate power while relying on other components for short-circuit or overload protection.

You’ll often find non-fused disconnects in residential and light commercial systems, such as air conditioners, lighting panels, and small machinery. These systems already have upstream protection in place, so additional fuses are not required.

Key Differences Between Fused and Non-Fused Disconnects

Although both provide safe isolation, their features and applications differ.

| Feature | Fused Disconnect | Non-Fused Disconnect |

| Protection | Built-in fuses that protect against overloads and short circuits. | No internal protection; relies on an upstream circuit breaker or fuse. |

| Maintenance | Requires replacing fuses after they blow. | Minimal maintenance; no fuse replacements needed. |

| Cost | Higher initial and replacement costs. | More affordable and easier to install. |

| Size | Slightly larger due to fuse holders. | Compact and space-saving. |

| Best For | High-power or standalone equipment needing local protection. | Circuits are already protected by upstream breakers or fuses. |

When to Use Each Type

When to Choose a Fused Disconnect

Fused disconnects are ideal for:

- Industrial machinery and heavy motors that draw large amounts of current.

- High fault current environments where equipment must handle power surges safely.

- Code-compliant installations where local protection is required by regulation.

In short, fused disconnects are best for systems that need both control and added protection.

When to Choose a Non-Fused Disconnect

Non-fused disconnects are well-suited for:

- Systems with existing protection, such as circuits backed by a breaker panel.

- Residential and light commercial equipment, like HVAC units or lighting systems.

- Budget-sensitive projects, where simple isolation is all that’s required.

They are easy to install, affordable, and dependable for everyday power disconnection.

Advantages and Limitations

| Fused Disconnects | Non-Fused Disconnects |

| Advantages | Advantages |

| • Built-in protection against overloads and short circuits.

• Safely handles higher fault currents. • Often required for compliance in industrial installations. |

• Simple design with fewer parts to maintain.

• Lower upfront cost and compact size. • Easy installation and long service life. |

| Limitations | Limitations |

| • Higher cost due to fuse components.

• Requires periodic fuse replacement. • Slightly larger and more complex to install. |

• No built-in protection against overloads or short circuits.

• Must be paired with upstream breakers or fuses. • Not suitable for high-fault or critical systems. |

How to Choose the Right Disconnect

Choosing between a fused and non-fused disconnect depends on your system’s protection needs and operating environment.

Here are some points to consider:

Protection Requirements

If no other protective device exists, choose a fused disconnect for built-in safety.

Upstream Protection

If your system already has a properly rated circuit breaker or fuse, a non-fused disconnect will usually be sufficient.

Fault Current Level

High-fault environments call for fused disconnects that can handle large surges safely.

Code and Compliance

Check local electrical codes and equipment manufacturer recommendations. Some applications legally require fused disconnects.

Maintenance and Cost

Fused disconnects require periodic maintenance and spare fuses, while non-fused units offer a low-maintenance, budget-friendly option.

Available Space

Non-fused disconnects are more compact and suitable for tight installations.

Conclusion

Both fused and non-fused disconnects are vital for maintaining electrical safety. The right choice depends on whether your system needs extra protection or only a reliable isolation switch. Use a fused disconnect if the circuit lacks upstream protection or operates under heavy electrical loads. Use a non-fused disconnect if the circuit already has proper protection and you simply need a safe way to cut power.

At Westhomes, we supply a wide range of high-quality electrical components for industrial and commercial applications. Our product line includes fused and non-fused disconnect switches, circuit breakers, and power distribution products built to meet international safety and performance standards.

If your business is upgrading its electrical systems or sourcing dependable components, our experts can help you select the right products for your needs. Contact us today to request a quotation or discuss bulk orders at info@westhomesele.com

--- END ---

In this blog

Featured Articles

Get A Free Quote